|

| LQ-160Z Large-scale Metallographic Cutting Machine LQ-160Z Large-scale Metallographic Cutting Machine LQ-160Z เครื่องตัดตัวอย่างโลหะขนาดใหญ่เป็นเครื่องตัดตัวอย่างโลหะอัตโนมัติควบคุม PLC ใช้ระบบควบคุมเพื่อขับเคลื่อนสเต็ปเปอร์ การควบคุมการเคลื่อนที่ของเซอร์โวมอเตอร์ การควบคุมทิศทาง X, Y, Z โดยอัตโนมัติและแม่นยำ ความแข็งของวัสดุจะเปลี่ยนความเร็วป้อนเพื่อให้ได้ผลการตัดที่เร็วที่สุด ความเร็วของแกนตัดจะถูกควบคุมโดยการแปลงความถี่ และสามารถปรับความเร็วของเส้นตัดของใบมีดตัดได้ มีความน่าเชื่อถือและการควบคุมที่สูงมาก Important notices and safety information

Main Specifications

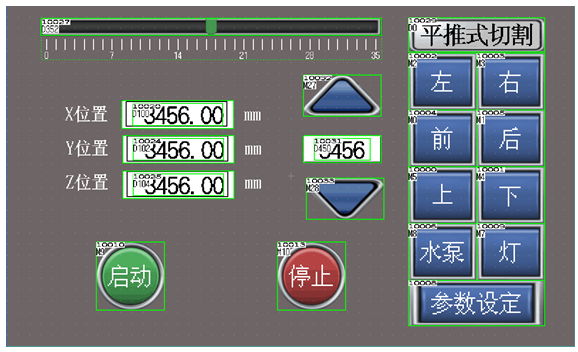

Brief introduction of each component function Touch screen:Set the time for the cutting machine to cut the sample; control the start and stop of the whole machine. Start button:Press the start button, the system sends power

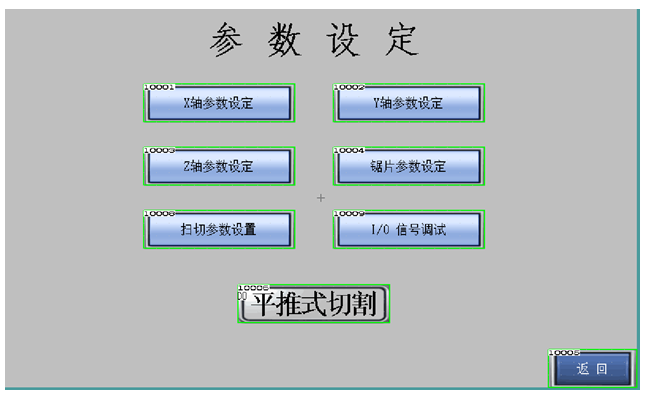

Operation keyboard and display Click the six parameter settings in the parameter setting to enter their respective setting screens.

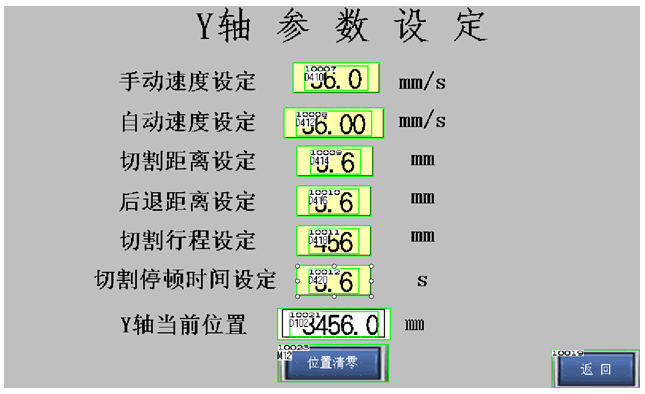

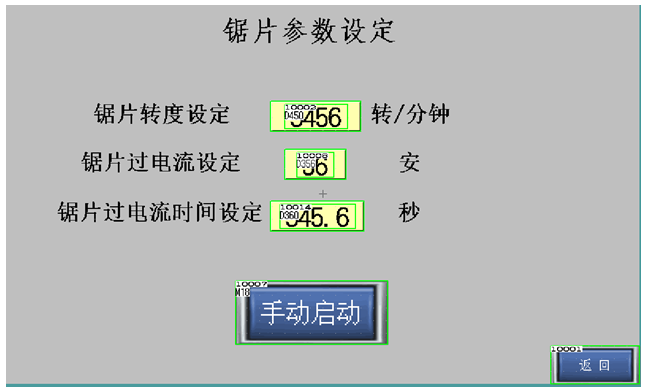

- Manual speed setting: Set the manual adjustment speed on the touch screen, you can adjust the value according to your needs to control the speed of manual movement. X operation screen Saw blade parameter setting

I/O signal debugging interface

Packing List

|

Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด SQ-60 SQ-80 SQ-100 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด SQ-60 SQ-80 SQ-100  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q2 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q2  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q-2A Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q-2A  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q-3A Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q-3A  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q-80Z Q100B Manual Autometic Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q-80Z Q100B Manual Autometic  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q-100B Automatic Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Q-100B Automatic  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด QG-4 Multifunctional Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด QG-4 Multifunctional  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด QG-4A Multifunctional Rapid Clamper Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด QG-4A Multifunctional Rapid Clamper  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Metacut-80 100 120 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Metacut-80 100 120  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Metacut-80L 100L 120L Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Metacut-80L 100L 120L  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Metacut-5000 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Metacut-5000  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LDQ-250 Manual Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LDQ-250 Manual  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LDQ-350 Manual Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LDQ-350 Manual  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LDQ-350A Manual-Automatic Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LDQ-350A Manual-Automatic  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LDQ-450 Automatic Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LDQ-450 Automatic  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LSQ-100 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด LSQ-100  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Qiege-60S Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Qiege-60S  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Qiege-100S Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Qiege-100S  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด DTQ-5 Low Speed Precise Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด DTQ-5 Low Speed Precise  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด GTQ-5000B Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด GTQ-5000B  Large metallographic sample cutting machine เครื่องตัดชิ้นงานละเอียดMETALL-350 Large metallographic sample cutting machine เครื่องตัดชิ้นงานละเอียดMETALL-350  Metallographic sample automatic cutting machine LQ-110Z Metallographic sample automatic cutting machine LQ-110Z  Multifunctional cutting machine QG-4A Multifunctional cutting machine QG-4A  Metallographic Precision Flat Cutting Machine PBQ-200 Metallographic Precision Flat Cutting Machine PBQ-200  Large-scale Metallographic Sample Cutting Machine LQ-110 Large-scale Metallographic Sample Cutting Machine LQ-110  Low-Speed Precision Cutting Machine DS-600 Low-Speed Precision Cutting Machine DS-600  GS-5000A High-speed precision cutting machine for metallographic samples GS-5000A High-speed precision cutting machine for metallographic samples  MODEL DM-1 METALLOGRAPHIC SPECIMEN QUICK DRYING MACHINE MODEL DM-1 METALLOGRAPHIC SPECIMEN QUICK DRYING MACHINE  MODEL Q-350A (SPECIALLY CUSTOMIZED) MODEL Q-350A (SPECIALLY CUSTOMIZED)  MODEL LDQ-400A (SPECIALLY CUSTOMIZED) MODEL LDQ-400A (SPECIALLY CUSTOMIZED)  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME250 AUTO Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME250 AUTO  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME400 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME400  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME300 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME300  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME250 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME250  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME150B Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด TIME150B  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด JMQ-12 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด JMQ-12  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด ZQ-100B Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด ZQ-100B  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด ZQ-80A Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด ZQ-80A  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด ZDQ-500 Automatic Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด ZDQ-500 Automatic  Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Metacut-5 Specimen Cutting Machine เครื่องตัดชิ้นงานละเอียด Metacut-5  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T201A Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T201A  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-GC450 Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-GC450  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T400 SO Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T400 SO  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T400 Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T400  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T350M Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T350M  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T255 Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Mecatome-T255  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T400 Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T400  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T300 Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T300  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T301 Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T301  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T200 Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T200  Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T100 Specimen Cutting Machine Korea เครื่องตัดชิ้นงานละเอียดเกาหลี Besttome-T100 |