|

| เครื่องทดสอบความตึงสายพาน Belt Tension Model (BANDO) เครื่องทดสอบความตึงสายพาน Belt Tension Model (BANDO) MADE IN JAPAN

สามารถติดต่อสอบถามได้ที่ 02-9744354-6 สายด่วน 088-7777277 - สามารถวัดได้แม้ในสภาพแวดล้อมที่มีเสียงดัง

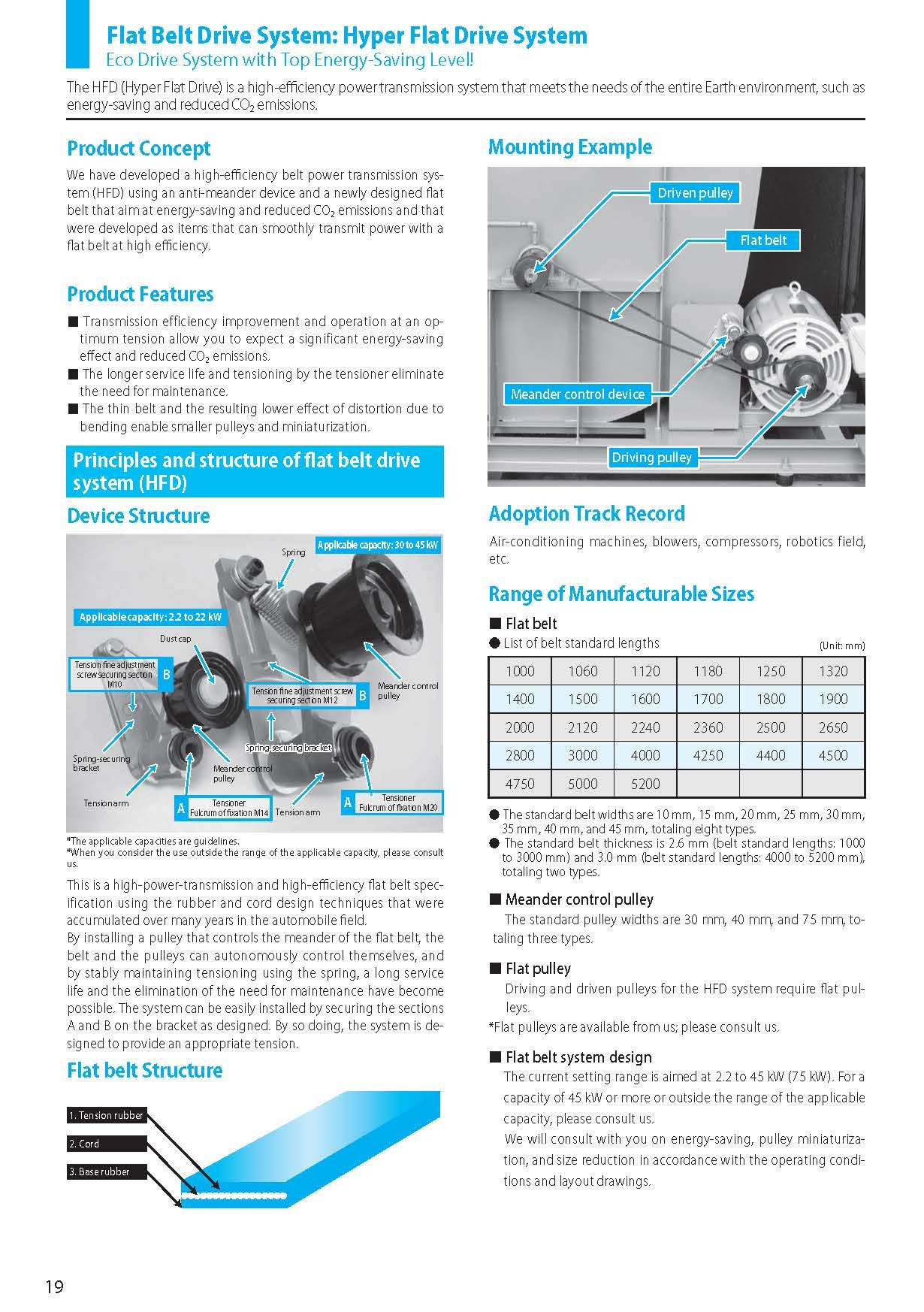

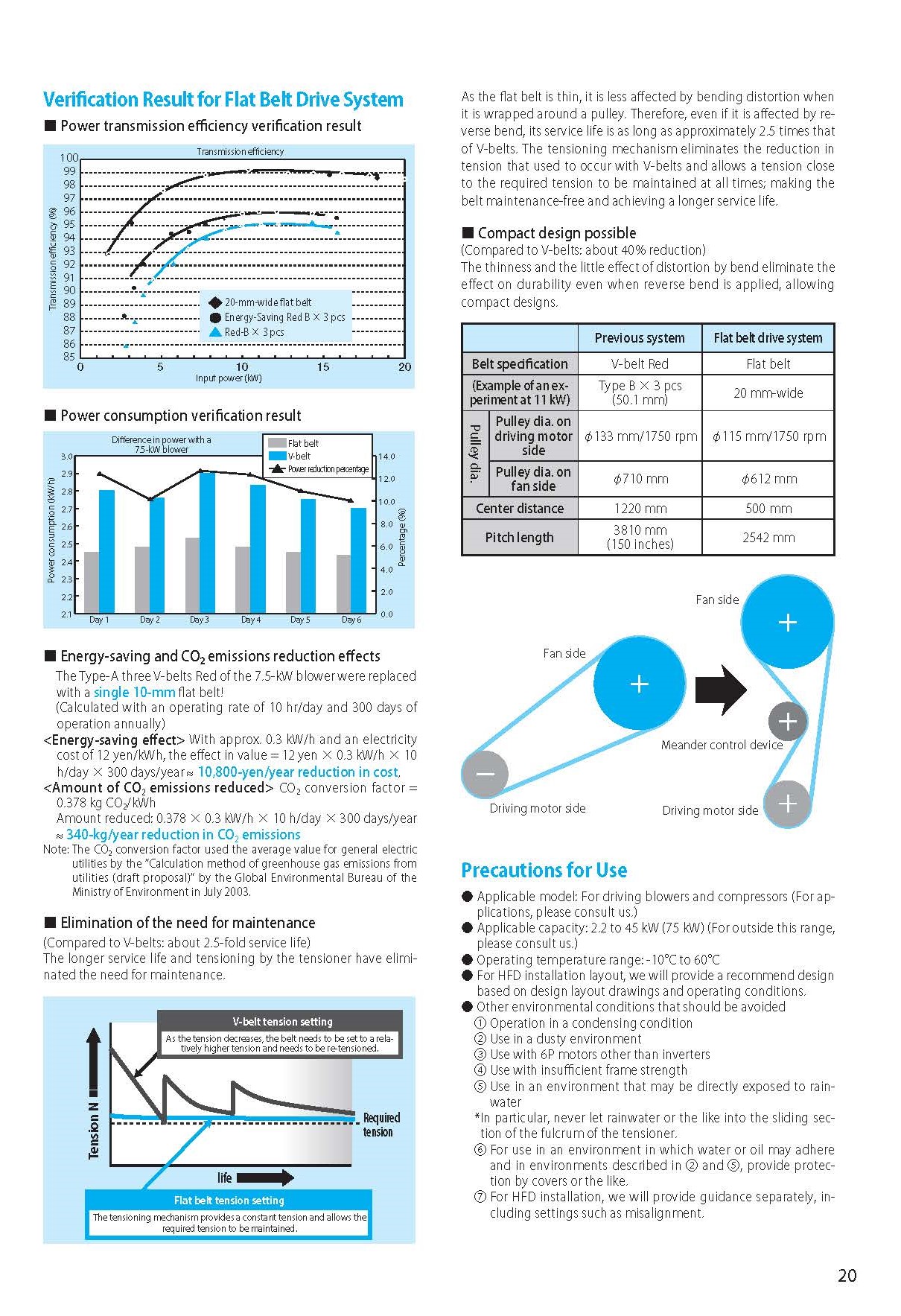

Product Features - Transmission efficiency improvement and operation at an optimum tension allow you to expect a significant energy-saving eff ect and reduced CO2 emissions. Features

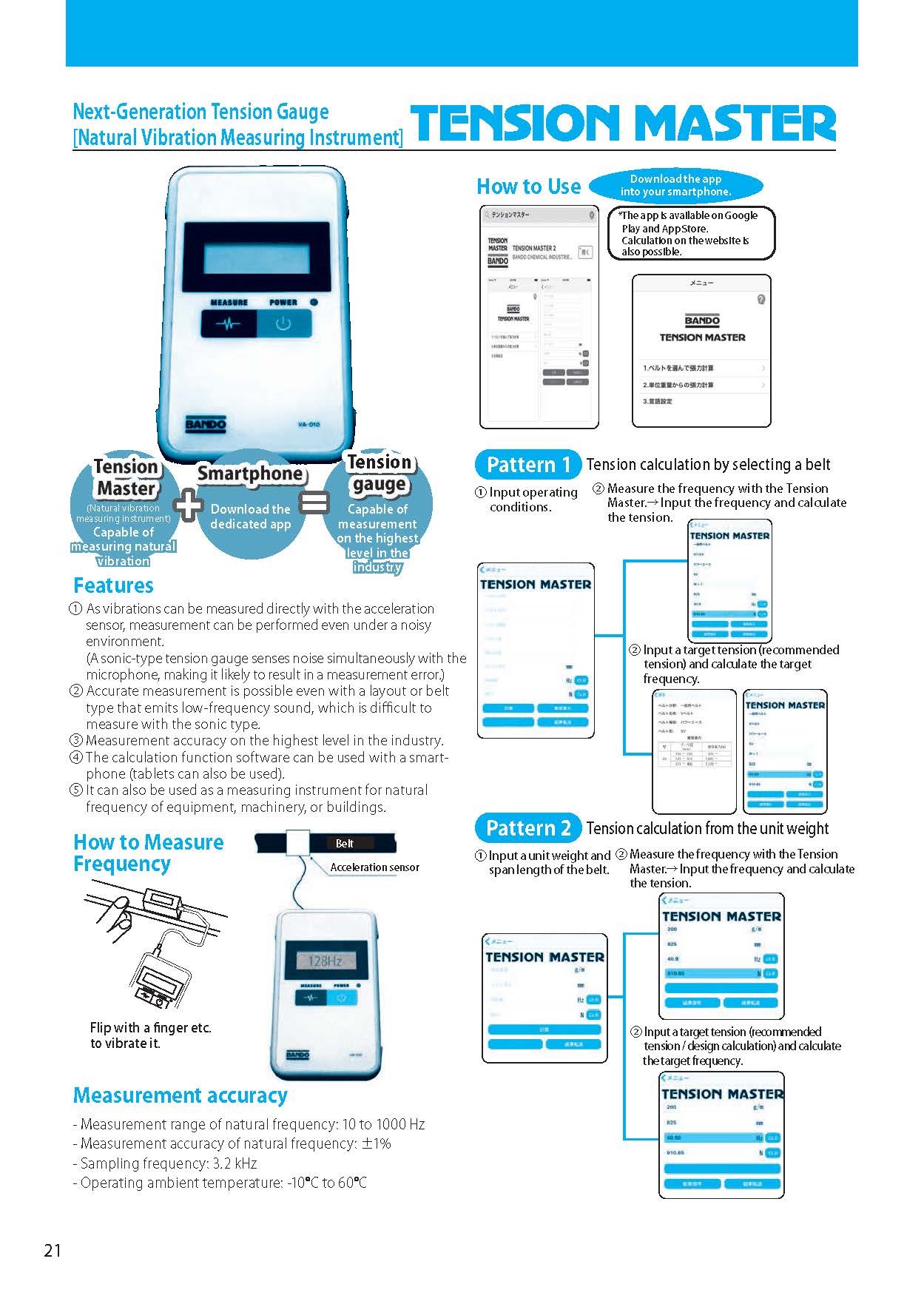

- As vibrations can be measured directly with the acceleration sensor, measurement can be performed even under a noisy

Measurement Accuracy - Measurement range of natural frequency: 10 to 1000 Hz Applications

|

เครื่องทดสอบความตึงสายพาน Belt Tension Model BDTM-201 เครื่องทดสอบความตึงสายพาน Belt Tension Model BDTM-201  เครื่องทดสอบความตึงสายพาน Belt Tension Model SK-8101 (KAISE) เครื่องทดสอบความตึงสายพาน Belt Tension Model SK-8101 (KAISE)  เครื่องทดสอบความตึงสายพาน Belt Tension Model BTT-2880-R8 (LANDTEK) เครื่องทดสอบความตึงสายพาน Belt Tension Model BTT-2880-R8 (LANDTEK)  เครื่องทดสอบความตึงสายพาน Belt Tension Model LTTS (LANDTEK) เครื่องทดสอบความตึงสายพาน Belt Tension Model LTTS (LANDTEK)  เครื่องทดสอบความตึงสายพาน Belt Tension Model HT-6510N (LANDTEK) เครื่องทดสอบความตึงสายพาน Belt Tension Model HT-6510N (LANDTEK)  เครื่องทดสอบความตึงสายพาน Belt Tension Model BTT-2880-R5 (LANDTEK) เครื่องทดสอบความตึงสายพาน Belt Tension Model BTT-2880-R5 (LANDTEK)  เครื่องทดสอบความตึงสายพาน Belt Tension Model BTT-2880 (LANDTEK) เครื่องทดสอบความตึงสายพาน Belt Tension Model BTT-2880 (LANDTEK)  เครื่องทดสอบความตึงสายพาน Belt Tension Model U-550 (UNITTA) เครื่องทดสอบความตึงสายพาน Belt Tension Model U-550 (UNITTA)  เครื่องทดสอบความตึงสายพาน Belt Tension Model GE-50576-A เครื่องทดสอบความตึงสายพาน Belt Tension Model GE-50576-A  เครื่องทดสอบความตึงสายพาน Belt Tension Model CDT-2000HD เครื่องทดสอบความตึงสายพาน Belt Tension Model CDT-2000HD  เครื่องทดสอบความตึงสายพาน Belt Tension Model BTM-TTC เครื่องทดสอบความตึงสายพาน Belt Tension Model BTM-TTC  เครื่องทดสอบความตึงสายพาน Belt Tension Model BTM-400 เครื่องทดสอบความตึงสายพาน Belt Tension Model BTM-400  เครื่องทดสอบความตึงสายพาน Belt Tension Model SRT-Series เครื่องทดสอบความตึงสายพาน Belt Tension Model SRT-Series  เครื่องทดสอบความตึงสายพาน Belt Tension Model BTG-Series เครื่องทดสอบความตึงสายพาน Belt Tension Model BTG-Series |