|

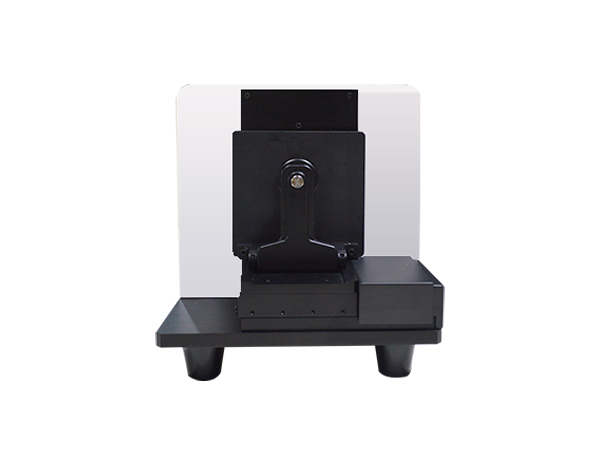

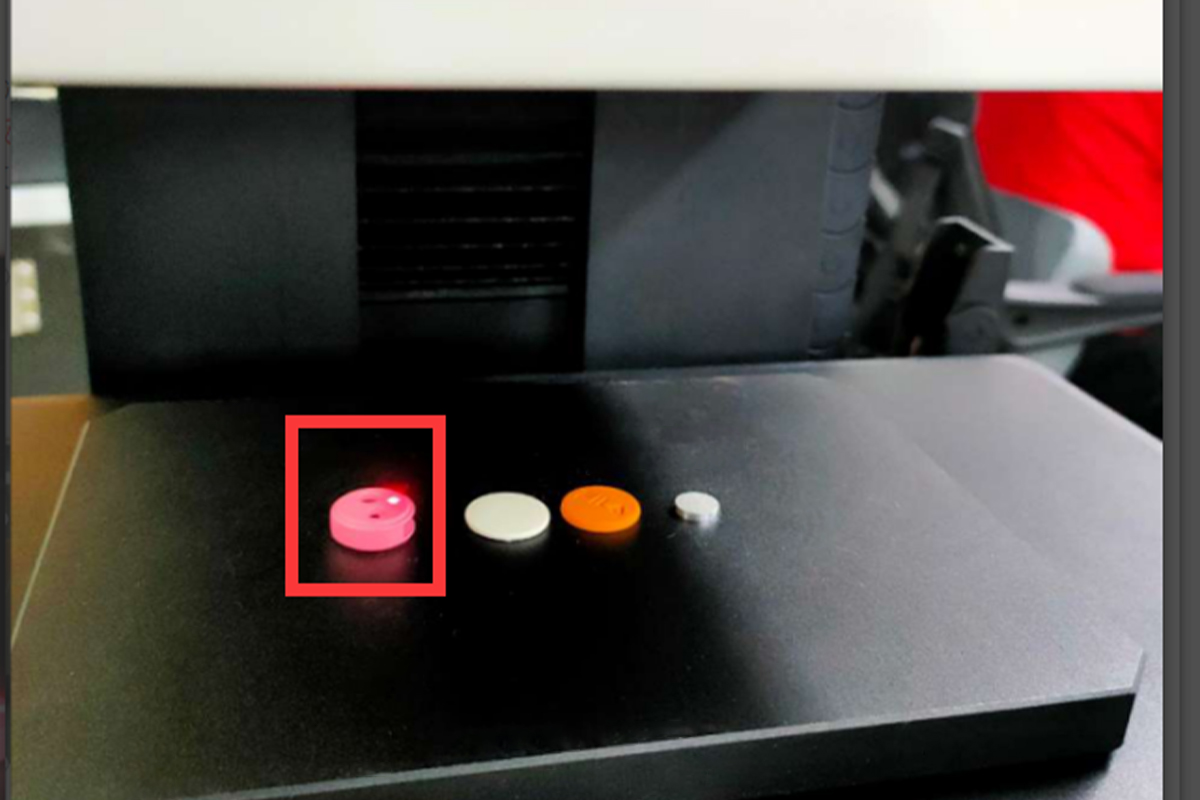

| เครื่องทดสอบเฉดสี DS-1000 Series Spectrophotometer (CHN) เครื่องทดสอบเฉดสี DS-1000 Series Spectrophotometer (CHN) เครื่องสเปกโตรโฟโตมิเตอร์ภาพซีรีส์ DigiSpec® เป็นเครื่องมือตรวจวัดสีที่ก้าวล้ำซึ่งสามารถนำไปใช้ในการวัดสีแทบทุกด้าน เครื่องสเปกโตรโฟโตมิเตอร์ภาพสามารถรับข้อมูลสีและสเปกตรัมสำหรับแต่ละจุดในภาพทั้งหมดต่อนาที โดยมีพื้นที่ขนาดเล็กเพียง 0.0016 มม.² (0.04 มม.*0.04 มม.) ระหว่างตารางนิ้ว

The DigiSpec® series image spectrophotometer is a groundbreaking color measurement instrument that can be used in virtually all areas of color measurement. The image spectrophotometer can obtain color and spectral data for each point in the entire image per minute, with an area as small as 0.0016mm² (0.04mm*0.04mm) between square inches. Epoch making color measuring instrument

Every inch is worth a penny

Digital transmission, fast and accurate color reproduction

Specfication

※ The measuring caliber is 25 * 25MM. After the instrument is calibrated, measure the BCRA white correction plate 30 times at an interval of 10 seconds ※※ Average value of measurement results of 12 BCRA ceramic standard color plates | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Spectrophotometer เครื่องวัดเฉดสี DC-50 Series Spectrophotometer เครื่องวัดเฉดสี DC-50 Series  เครื่องวัดเฉดสี Colorimeter DS 528 Series (CHN) เครื่องวัดเฉดสี Colorimeter DS 528 Series (CHN)  Benchtop Spectrophoto Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ ITK-YS6003 Benchtop Spectrophoto Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ ITK-YS6003  เครื่องวัดเฉดสี Colorimeter PS-2070-PS2080 Series (3nh) เครื่องวัดเฉดสี Colorimeter PS-2070-PS2080 Series (3nh)  เครื่องวัดเฉดสี Colorimeter PS-2050-PS2060 Series (3nh) เครื่องวัดเฉดสี Colorimeter PS-2050-PS2060 Series (3nh)  เครื่องวัดเฉดสี Colorimeter PS-2030-PS2040 Series (3nh) เครื่องวัดเฉดสี Colorimeter PS-2030-PS2040 Series (3nh)  Color spectrum desktop liquid colorimeter DS-812N / DS-816N Color spectrum desktop liquid colorimeter DS-812N / DS-816N  การวัดไฮเปอร์สเปกตรัม UAV Near-Infrared hyperspectral Measurement FS63 series (CHN) การวัดไฮเปอร์สเปกตรัม UAV Near-Infrared hyperspectral Measurement FS63 series (CHN)  การวัดไฮเปอร์สเปกตรัม UAV hyperspectral Measurement FS60 series (CHN) การวัดไฮเปอร์สเปกตรัม UAV hyperspectral Measurement FS60 series (CHN)  เครื่องทดสอบเฉดสี Imaging hyperspectral camera FS2X series (CHN) เครื่องทดสอบเฉดสี Imaging hyperspectral camera FS2X series (CHN)  เครื่องทดสอบเฉดสี Portable Transmittance Tester CT-Series (CHN) เครื่องทดสอบเฉดสี Portable Transmittance Tester CT-Series (CHN)  เครื่องทดสอบเฉดสี Spectral Colorimeter CR series (CHN) เครื่องทดสอบเฉดสี Spectral Colorimeter CR series (CHN)  เครื่องทดสอบเฉดสี DS-700-C Series Spectrophotometer (CHN) เครื่องทดสอบเฉดสี DS-700-C Series Spectrophotometer (CHN)  Bench-top spectrophotometer เครื่องวัดเฉดสีแบบตั้งโต๊ะ DS-D Series Bench-top spectrophotometer เครื่องวัดเฉดสีแบบตั้งโต๊ะ DS-D Series  PS20 series Spectrocoloriemter เครื่องวัดเฉดสี(3NH) PS20 series Spectrocoloriemter เครื่องวัดเฉดสี(3NH)  DS-200 Colorimeter เครื่องวัดเปรียบเทียบสี (CHN) DS-200 Colorimeter เครื่องวัดเปรียบเทียบสี (CHN)  Spectroscopic Chromatography CR8+ Spectroscopic Chromatography CR8+  DS-600 Spectrophotometer เครื่องวัดเฉดสี (CHN) DS-600 Spectrophotometer เครื่องวัดเฉดสี (CHN)  Color Sensor CRX-50 กล้องทดสอบส่องเทียบเฉดสี Color Sensor CRX-50 กล้องทดสอบส่องเทียบเฉดสี  เครื่องทดสอบเฉดสี DS-700Series Spectrophotometer (CHN) เครื่องทดสอบเฉดสี DS-700Series Spectrophotometer (CHN)  กล้องถ่ายภาพวัดเฉดสี Hyperspectral Figspectral-FS Series กล้องถ่ายภาพวัดเฉดสี Hyperspectral Figspectral-FS Series  Spectrophoto Meter เครื่องวัดเฉดสีตั้งโต๊ะ CS-826 (CHN) Spectrophoto Meter เครื่องวัดเฉดสีตั้งโต๊ะ CS-826 (CHN)  Spectrophoto Meter เครื่องวัดเฉดสีตั้งโต๊ะ CS-828 (CHN) Spectrophoto Meter เครื่องวัดเฉดสีตั้งโต๊ะ CS-828 (CHN)  Spectrophoto Meter เครื่องวัดเฉดสี CS-420 (CHN) Spectrophoto Meter เครื่องวัดเฉดสี CS-420 (CHN)  Colormeter Pro เครื่องเปรียบเทียบสี Colormeter CMYK (CHN) Colormeter Pro เครื่องเปรียบเทียบสี Colormeter CMYK (CHN)  Colorimeter เครื่องเปรียบเทียบสี CS-410 (CHN) Colorimeter เครื่องเปรียบเทียบสี CS-410 (CHN)  Spectrophoto Meter เครื่องวัดเฉดสี CS-392 (CHN) Spectrophoto Meter เครื่องวัดเฉดสี CS-392 (CHN)  Spectrophoto Meter เครื่องวัดเฉดสี CS-500-SERIES (CHN) Spectrophoto Meter เครื่องวัดเฉดสี CS-500-SERIES (CHN)  Spectrophoto Meter เครื่องวัดเฉดสี TS70-SERIES (3NH) Spectrophoto Meter เครื่องวัดเฉดสี TS70-SERIES (3NH)  Colormeter Pro เครื่องเปรียบเทียบสี Colormeter Pro (CHN) Colormeter Pro เครื่องเปรียบเทียบสี Colormeter Pro (CHN)  Spectrophoto Meter เครื่องวัดเฉดสี YD5050(3NH) Spectrophoto Meter เครื่องวัดเฉดสี YD5050(3NH)  Spectrophoto Meter เครื่องวัดเฉดสี YS4580(3NH) Spectrophoto Meter เครื่องวัดเฉดสี YS4580(3NH)  Colorimeter เครื่องเปรียบเทียบสี CS-280 Colorimeter เครื่องเปรียบเทียบสี CS-280  Colorimeter เครื่องเปรียบเทียบสี CS-260 Colorimeter เครื่องเปรียบเทียบสี CS-260  Colorimeter เครื่องเปรียบเทียบสี CS-220 Colorimeter เครื่องเปรียบเทียบสี CS-220  Colorimeter เครื่องเปรียบเทียบสี CS-210 Colorimeter เครื่องเปรียบเทียบสี CS-210  Colorimeter เครื่องเปรียบเทียบสี CS-200 Colorimeter เครื่องเปรียบเทียบสี CS-200  Colorimeter เครื่องเปรียบเทียบสี CS-10 Colorimeter เครื่องเปรียบเทียบสี CS-10  Spectrophoto Meter เครื่องวัดเฉดสี CM-200S Spectrophoto Meter เครื่องวัดเฉดสี CM-200S  Spectrophoto Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ CS-820N Spectrophoto Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ CS-820N  Spectrophoto Meter เครื่องวัดเฉดสี ITK-YS3060 Spectrophoto Meter เครื่องวัดเฉดสี ITK-YS3060  Spectrophoto Meter เครื่องวัดเฉดสี ITK-YS3010 Spectrophoto Meter เครื่องวัดเฉดสี ITK-YS3010  Spectrophoto Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ ITK-YS6060 Spectrophoto Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ ITK-YS6060  Spectrophoto Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ ITK-YS6010 Spectrophoto Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ ITK-YS6010  Spectrophotometer เครื่องวัดเฉดสี CS-390 Three Angles Color Spectrophotometer เครื่องวัดเฉดสี CS-390 Three Angles Color  Spectrophotometer เครื่องวัดเฉดสี CS-600CG Spectrophotometer เครื่องวัดเฉดสี CS-600CG  Color and Haze เครื่องวัดสีและหมอกควัน CS-700 และ CS-720 Color and Haze เครื่องวัดสีและหมอกควัน CS-700 และ CS-720  Spectrophotometer เครื่องวัดเฉดสีแบบตั้งโต๊ะ CS-810 Spectrophotometer เครื่องวัดเฉดสีแบบตั้งโต๊ะ CS-810  Spectro Photo Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ Model CS-801 Spectro Photo Meter เครื่องวัดเฉดสีแบบตั้งโต๊ะ Model CS-801  Spectrophotometer เครื่องวัดเฉดสี CS-801 Spectrophotometer เครื่องวัดเฉดสี CS-801  Spectrophotometer เครื่องวัดเฉดสี SC-20 Spectrophotometer เครื่องวัดเฉดสี SC-20  Spectrophotometer เครื่องวัดเฉดสี SC-80 Spectrophotometer เครื่องวัดเฉดสี SC-80  Spectro Photo Meter เครื่องวัดเฉดสีแบบน้ำ Model CS-800 Spectro Photo Meter เครื่องวัดเฉดสีแบบน้ำ Model CS-800  Spectrophotometer เครื่องวัดเฉดสีผง Model CS 600 Spectrophotometer เครื่องวัดเฉดสีผง Model CS 600  Spectrophotometer เครื่องวัดเฉดสี แบบเปียก Model CS 820 Spectrophotometer เครื่องวัดเฉดสี แบบเปียก Model CS 820  Spectrophotometer เครื่องวัดเฉดสี Model NH 300 Spectrophotometer เครื่องวัดเฉดสี Model NH 300  Spectrophotometer NR-110 Spectrophotometer NR-110  Spectrophotometer เครื่องวัดเฉดสี NR-200 Spectrophotometer เครื่องวัดเฉดสี NR-200  Spectrophotometer เครื่องวัดเฉดสี NH-310 Spectrophotometer เครื่องวัดเฉดสี NH-310  Spectrophotometer เครื่องวัดเฉดสี NS-800 Spectrophotometer เครื่องวัดเฉดสี NS-800 |