|

| Universal Material Testing Instrument RTG Series (JAPAN) Universal Material Testing Instrument RTG Series (JAPAN)

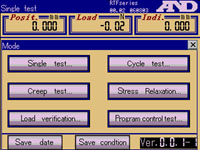

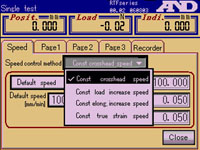

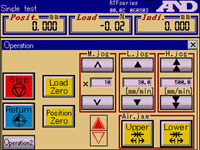

Color Touch panel

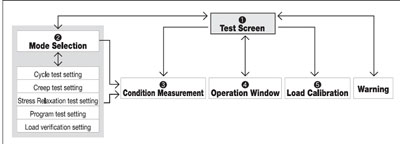

Either the color touch panel OP-01 or MSAT data processing software (on a personal computer) can be selected for user interface.

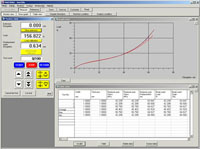

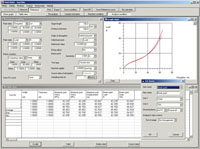

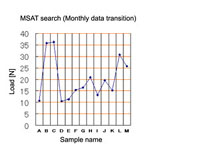

MSAT (Multi Signal Analysis Testing)

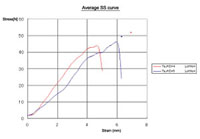

Standard layout setting during a measurement

Commander Applications

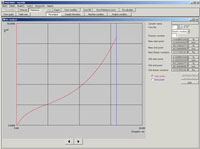

Applications

Applied testing devices for temperature / environment test

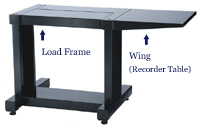

Data Recorder

Load frame table

Dimensions (mm) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

เครื่องทดสอบแรงดึง Universal tensile model 5-300TON เครื่องทดสอบแรงดึง Universal tensile model 5-300TON  เครื่องทดสอบแรงดึง Universal tensile model 0-1000KN เครื่องทดสอบแรงดึง Universal tensile model 0-1000KN  เครื่องทดสอบแรงดึง Universal tensile model IT-800, IT800B เครื่องทดสอบแรงดึง Universal tensile model IT-800, IT800B  เครื่องทดสอบแรงดึง Universal tensile model IT-8000A เครื่องทดสอบแรงดึง Universal tensile model IT-8000A  เครื่องทดสอบแรงดึง Universal tensile model IT-8001A/IT-8001 เครื่องทดสอบแรงดึง Universal tensile model IT-8001A/IT-8001  เครื่องทดสอบแรงดึง Universal tensile model IT-8002/IT-8010/IT-8010A เครื่องทดสอบแรงดึง Universal tensile model IT-8002/IT-8010/IT-8010A  เครื่องทดสอบแรงดึง Universal tensile model IT-8010L/ IT-8010W เครื่องทดสอบแรงดึง Universal tensile model IT-8010L/ IT-8010W  เครื่องทดสอบแรงดึง Universal tensile model IT-8003/IT-8004/IT-8007 เครื่องทดสอบแรงดึง Universal tensile model IT-8003/IT-8004/IT-8007  เครื่องทดสอบแรงดึงและแรงกดของสปริงแบบดิจิทัลอัตโนมัติ Digital Automatic Spring Tension & Compression Testing Machine Model : ITK-Z200N (LONROY) เครื่องทดสอบแรงดึงและแรงกดของสปริงแบบดิจิทัลอัตโนมัติ Digital Automatic Spring Tension & Compression Testing Machine Model : ITK-Z200N (LONROY)  เครื่องทดสอบแรงดึงและแรงกดของสปริงแบบดิจิทัลอัตโนมัติ Digital Automatic Spring Tension & Compression Testing Machine Model : ITK-ZJ50N (LONROY) เครื่องทดสอบแรงดึงและแรงกดของสปริงแบบดิจิทัลอัตโนมัติ Digital Automatic Spring Tension & Compression Testing Machine Model : ITK-ZJ50N (LONROY)  Lr-F037 Computer Control Carton Compression Tester Pressure Test Equipment Lr-F037 Computer Control Carton Compression Tester Pressure Test Equipment  Digital Automatic Spring Tension & Compression Testing Machine ZCTL-Z500N (ZCTL) Digital Automatic Spring Tension & Compression Testing Machine ZCTL-Z500N (ZCTL)  เครื่องเตรียมชิ้นงานสำหรับเครื่องทดสอบแรงดึงแรงกด Pneumatic Punching Machine Model ITK-A016 เครื่องเตรียมชิ้นงานสำหรับเครื่องทดสอบแรงดึงแรงกด Pneumatic Punching Machine Model ITK-A016  เครื่องทดสอบแรงดึง Digital Automatic Spring Tension & Compression Testing Machine LR-D200N เครื่องทดสอบแรงดึง Digital Automatic Spring Tension & Compression Testing Machine LR-D200N  เครื่องทดสอบแรงดึง Spring Tensile & Compression Testing Machine SPS-W100 (SUNPOC) เครื่องทดสอบแรงดึง Spring Tensile & Compression Testing Machine SPS-W100 (SUNPOC)  High load type Automatic Spring TesterASP high load type series (Digitech Japan) High load type Automatic Spring TesterASP high load type series (Digitech Japan)  Automatic Torsion Spring TesterMODEL STP series (Digitech Japan) Automatic Torsion Spring TesterMODEL STP series (Digitech Japan)  Automatic Spring Tester MODEL ASP series (Digitech Japan) Automatic Spring Tester MODEL ASP series (Digitech Japan)  เครื่องทดสอบแรงดึง Universal testing Machine model QC-505M1F (Come-Tech) เครื่องทดสอบแรงดึง Universal testing Machine model QC-505M1F (Come-Tech)  เครื่องทดสอบแรงดึง Universal testing Machine model QC-952 Hydraulic (Come-Tech) เครื่องทดสอบแรงดึง Universal testing Machine model QC-952 Hydraulic (Come-Tech)  เครื่องทดสอบแรงดึง Universal testing Machine model QC-501M1F (Come-Tech) เครื่องทดสอบแรงดึง Universal testing Machine model QC-501M1F (Come-Tech)  Material Testing Instruments STA (JAPAN) Material Testing Instruments STA (JAPAN)  Tabletop Material Testing Instruments STB Series (JAPAN) Tabletop Material Testing Instruments STB Series (JAPAN)  Table Top Universal Testing Machine MCT Series (JAPAN) Table Top Universal Testing Machine MCT Series (JAPAN)  Universal Testing Instruments RTF Series (JAPAN) Universal Testing Instruments RTF Series (JAPAN)  เครื่องทดสอบแรงดึง Universal Testing Machine WAL-Series (HST) เครื่องทดสอบแรงดึง Universal Testing Machine WAL-Series (HST)  เครื่องทดสอบแรงดึง Universal Testing Machine WAW-F Series (HST) เครื่องทดสอบแรงดึง Universal Testing Machine WAW-F Series (HST)  เครื่องทดสอบแรงดึง Universal Testing Machine WAW-L Series (HST) เครื่องทดสอบแรงดึง Universal Testing Machine WAW-L Series (HST)  เครื่องทดสอบแรงดึง Universal Testing Machine WAW-A Series (HST) เครื่องทดสอบแรงดึง Universal Testing Machine WAW-A Series (HST)  เครื่องทดสอบแรงดึง Universal Testing Machine WEW-D Series (HST) เครื่องทดสอบแรงดึง Universal Testing Machine WEW-D Series (HST)  เครื่องทดสอบแรงดึง Universal Testing Machine WAW-D Series (HST) เครื่องทดสอบแรงดึง Universal Testing Machine WAW-D Series (HST)  เครื่องทดสอบแรงดึง Universal Testing Machine WDW-E Series (HST) เครื่องทดสอบแรงดึง Universal Testing Machine WDW-E Series (HST)  เครื่องทดสอบแรงดึง Universal Testing Machine WDW-Series (HST) เครื่องทดสอบแรงดึง Universal Testing Machine WDW-Series (HST)  KJ-6003A Manual sample cutter KJ-6003A Manual sample cutter  เครื่องทดสอบแรงดึง Universal Testing Machine SJL-5K (SUNDOO) เครื่องทดสอบแรงดึง Universal Testing Machine SJL-5K (SUNDOO)  เครื่องทดสอบแรงดึง Universal Testing Machine SJL-1K-2K (SUNDOO) เครื่องทดสอบแรงดึง Universal Testing Machine SJL-1K-2K (SUNDOO)  เครื่องทดสอบแรงดึง Universal Testing Machine SJL-500V (SUNDOO) เครื่องทดสอบแรงดึง Universal Testing Machine SJL-500V (SUNDOO)  เครื่องทดสอบแรงดึง Universal Testing Machine SJL-500H (SUNDOO) เครื่องทดสอบแรงดึง Universal Testing Machine SJL-500H (SUNDOO)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC SST-SFT-Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC SST-SFT-Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC MAX-R2KN-Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC MAX-R2KN-Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC UFT-Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC UFT-Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC MAX XY-Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC MAX XY-Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC PRO-T-Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC PRO-T-Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC ACE-Series และ ACE-F Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC ACE-Series และ ACE-F Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC JOB-Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC JOB-Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC Pro-HI Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC Pro-HI Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC Spring Tester PRO-Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC Spring Tester PRO-Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC Spring Tester PRO-01S (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC Spring Tester PRO-01S (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC MAX-Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC MAX-Series (Japan)  เครื่องทดสอบแรงดึง Universal Testing Machine JISC HIT-Series (Japan) เครื่องทดสอบแรงดึง Universal Testing Machine JISC HIT-Series (Japan)  เครื่องทดสอบแรงดึง แรงกด KJ-1100 เครื่องทดสอบแรงดึง แรงกด KJ-1100  เครื่องทดสอบแรงดึง Universal tensile model ITK-C006 (200KN) เครื่องทดสอบแรงดึง Universal tensile model ITK-C006 (200KN)  เครื่องทดสอบแรงดึงแรงกดสปริง Spring Tester Machine TLS-W50 เครื่องทดสอบแรงดึงแรงกดสปริง Spring Tester Machine TLS-W50  เครื่องทดสอบแรงดึง Universal testing Machine Model UNITEST M2 เครื่องทดสอบแรงดึง Universal testing Machine Model UNITEST M2  เครื่องทดสอบแรงดึง Universal testing Machine Model UNITEST MD เครื่องทดสอบแรงดึง Universal testing Machine Model UNITEST MD  เครื่องทดสอบแรงดึง Universal testing Machine Model UNITEST M1 เครื่องทดสอบแรงดึง Universal testing Machine Model UNITEST M1  เครื่องทดสอบแรงดึง Universal testing Machine Model TO-101G เครื่องทดสอบแรงดึง Universal testing Machine Model TO-101G  เครื่องทดสอบแรงดึง Universal testing Machine model WES-300B (SUNPOC) เครื่องทดสอบแรงดึง Universal testing Machine model WES-300B (SUNPOC)  เครื่องทดสอบแรงดึง Universal testing Machine model WEW-300B (SUNPOC) เครื่องทดสอบแรงดึง Universal testing Machine model WEW-300B (SUNPOC)  เครื่องทดสอบแรงดึง Universal testing Machine model WAW-300B (SUNPOC) เครื่องทดสอบแรงดึง Universal testing Machine model WAW-300B (SUNPOC)  เครื่องทดสอบแรงดึง Universal testing Machine model C3300 (SUNPOC) เครื่องทดสอบแรงดึง Universal testing Machine model C3300 (SUNPOC)  เครื่องทดสอบแรงดึง Universal testing Machine model C3370 (SUNPOC) เครื่องทดสอบแรงดึง Universal testing Machine model C3370 (SUNPOC)  เครื่องทดสอบแรงดึง Universal testing Machine model C2200 (SUNPOC) เครื่องทดสอบแรงดึง Universal testing Machine model C2200 (SUNPOC)  เครื่องทดสอบแรงกด กล่อง Type Box Compression Tester ITK-8210 เครื่องทดสอบแรงกด กล่อง Type Box Compression Tester ITK-8210  เครื่องทดสอบแรงดึง Universal testing Machine model QC-954 Hydraulic (Come-Tech) เครื่องทดสอบแรงดึง Universal testing Machine model QC-954 Hydraulic (Come-Tech)  เครื่องทดสอบแรงดึง Universal testing Machine model QC-506M1F (Come-Tech) เครื่องทดสอบแรงดึง Universal testing Machine model QC-506M1F (Come-Tech)  เครื่องทดสอบแรงดึง Universal testing Machine model QC-506D1 (Come-Tech) เครื่องทดสอบแรงดึง Universal testing Machine model QC-506D1 (Come-Tech)  เครื่องทดสอบแรงดึง Universal testing Machine model QC-548D2 (Come-Tech) เครื่องทดสอบแรงดึง Universal testing Machine model QC-548D2 (Come-Tech)  เครื่องทดสอบแรงดึง Universal testing Machine model QC-513M1F (Come-Tech) เครื่องทดสอบแรงดึง Universal testing Machine model QC-513M1F (Come-Tech)  เครื่องทดสอบแรงดึง Universal testing Machine model QC-508M1F (Come-Tech) เครื่องทดสอบแรงดึง Universal testing Machine model QC-508M1F (Come-Tech)  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-C002 เครื่องทดสอบแรงดึง Universal testing Machine model ITK-C002  เครื่องทดสอบแรงดึง Universal tensile model Multi-UT เครื่องทดสอบแรงดึง Universal tensile model Multi-UT  เครื่องทดสอบแรงดึง Universal tensile model DHFM-SHFM เครื่องทดสอบแรงดึง Universal tensile model DHFM-SHFM  เครื่องทดสอบแรงดึง Universal tensile model DFM-600KN เครื่องทดสอบแรงดึง Universal tensile model DFM-600KN  เครื่องทดสอบแรงดึง Universal tensile model DFM-300KN เครื่องทดสอบแรงดึง Universal tensile model DFM-300KN  เครื่องทดสอบแรงดึง Universal tensile model DFM-150KN เครื่องทดสอบแรงดึง Universal tensile model DFM-150KN  เครื่องทดสอบแรงดึง Universal tensile model DFM-100KN เครื่องทดสอบแรงดึง Universal tensile model DFM-100KN  เครื่องทดสอบแรงดึง Universal tensile model DTM-100KN เครื่องทดสอบแรงดึง Universal tensile model DTM-100KN  เครื่องทดสอบแรงดึง Universal tensile model DTM-50KN เครื่องทดสอบแรงดึง Universal tensile model DTM-50KN  เครื่องทดสอบแรงดึง Universal tensile model DSTM-25KN เครื่องทดสอบแรงดึง Universal tensile model DSTM-25KN  เครื่องทดสอบแรงดึง Universal tensile model DSTM-20KN เครื่องทดสอบแรงดึง Universal tensile model DSTM-20KN  เครื่องทดสอบแรงดึง Universal tensile model DSTM-10KN เครื่องทดสอบแรงดึง Universal tensile model DSTM-10KN  เครื่องทดสอบแรงดึง Universal tensile model DSTM-5KN เครื่องทดสอบแรงดึง Universal tensile model DSTM-5KN  เครื่องทดสอบแรงกด Foam Tester 5KN เครื่องทดสอบแรงกด Foam Tester 5KN  เครื่องทดสอบแรงดึง Universal tensile model DSTM2.5KN เครื่องทดสอบแรงดึง Universal tensile model DSTM2.5KN  เครื่องทดสอบแรงดึง Universal testing Machine model VT-200(KOREA) เครื่องทดสอบแรงดึง Universal testing Machine model VT-200(KOREA)  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUH-8A Hydraulic เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUH-8A Hydraulic  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2H เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2H  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2S เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2S  เครื่องทดสอบแรงดึง Univesal testing Machine model ITK-KUM-2AN เครื่องทดสอบแรงดึง Univesal testing Machine model ITK-KUM-2AN  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2AS เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2AS  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2B HYDRAULIC เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2B HYDRAULIC  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2B เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2B  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-6A เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-6A  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2N เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KUM-2N  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-7000M-1N เครื่องทดสอบแรงดึง Universal testing Machine model ITK-7000M-1N  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KU7000M-1S เครื่องทดสอบแรงดึง Universal testing Machine model ITK-KU7000M-1S  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-1066A&B เครื่องทดสอบแรงดึง Universal testing Machine model ITK-1066A&B  เครื่องทดสอบแรงดึง Universal testing Machine model ITK-C10KN เครื่องทดสอบแรงดึง Universal testing Machine model ITK-C10KN |