|

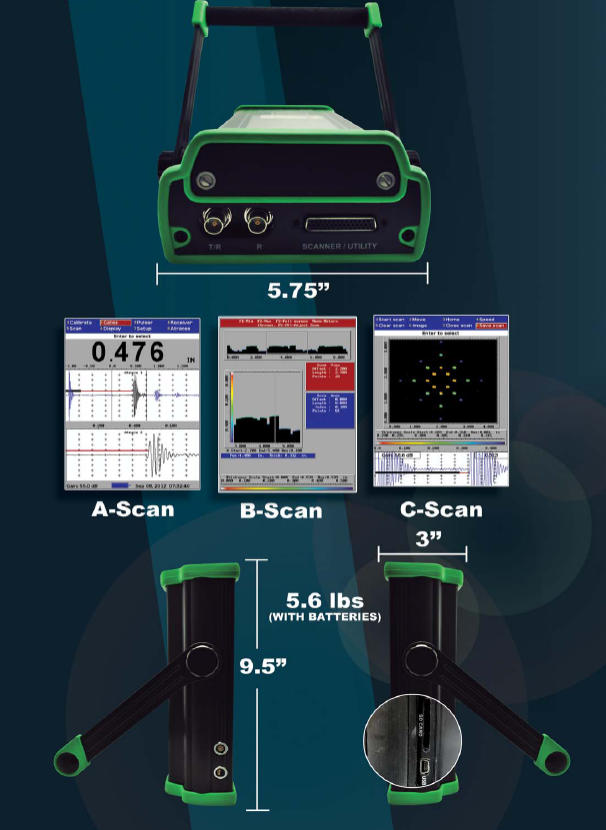

| Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model High Preformance Imaging Flaw Detector High Preformance Imaging Flaw Detector เครื่องวัดความหนาเนื้อเหล็ก , รอยแตก,วัดโพรงอากาศ,ตรวจสอบจุดบกพร่อง แสดงหน้าจอ 3 มิติ

Specifications

Applications - Flaw detection and thickness gauging in most materials - Corrosion mapping on pipes, tanks, vessels - A-, B-, C-csan imaging - Composite Inspection using thickness or amplitude flaw gates

Features - All-in-one high-resolution, high-speed, flaw detector, thickness gauge and B-, C-scan imaging system - Robust alumium case with rabber end caps - 5.7" VGA sun readable Color display - Spike and square wave tuneable pulser, 500Hz PRF - Compatible with range of manual and automatic scanners for encoded B-scan and C-scan imaging

Introduction Flaw detection is the process of identifying and sizing sub-surface defaces in material. One of the most common techniques to identify defacets is ultrasonic inspection where sound waves, propagated through the material, are used to identify such anomalies. Flaw detection can be applied in almost any industry from composites and metals used in aerospace, to petrochemical oil and gas pipelines, storage tanks and power generation including nuclear power. The most common anomalies include cracks, voide and porosity in metals, ceramics and plastics in addition to delaminations and disbonds in composites. Imaging is the ability to generate a full-field results image, or plan view mapping, of an area of interest. So called C-Scans are generated using manual or automated scanners, are easy to understand, serve as a digital archive and reduce inspection time dramatically

The raptor is an all-in-one high-resolution thickness gauge, flaw detector and imaging flaw detector capable of driving a range of manual and automatic scanners. The Raptor is unique with its robust aluminum construction, class leading PRF, powerful spike or tuneable square wave pulser and large sun readable screen. As a high-speed flaw detector or thickness gauge, the Raptor offers great versatility- capable of operating in a frequency range from 0.5MHz to 30Mhz it can run single, dual, contact, angle, delay line and immersion transducers. Dual gates, a 20 point DAC, peak echo hold, weld trig and many other features are all included as standard. For the added capability of imaging, threr is no need to upgrade or buy a complete new system, simply choose the right scanner for the application and the Raptor can generate C-scan images instantly. Data storage is through an SD card for easy transfer and a field-replaceable Li-ion battery gives 8-10 hours longevity.

Advanced Imaging Capability The power of an image cannot be understated and can significantly speed up an inspection and help with interpretation. The Raptor is compatible with a range of manual and automatic scanners. The standard software can soft can define the scan area, index resolution and speed and displays the resulting images live as they are generated. A full suite of software functiongs is included for further analysis of the results, including B-scan section, 3D images, statistical tools for defect sizing and much more. The scanner can also be positioned back to any point of interest. The display can run in Splitview screen mode with auto-tracking of the echo and a simultaneous view of the B- or C-scan and the live A-trace. The combined imaging system boasts an unmatched performance for a very low price and is a perfect way to enter the world of imaging and speed up inspection processes in hard to reach areas.

Tags: เครื่องวัดความหนาultrasonic, เครื่องวัดความหนาเหล็ก, เครื่องวัดความหนาผิวเคลือบ, เครื่องวัดความหนาพลาสติก,เครื่องวัดความหนาดิจิตอล,ultrasonic thickness gauge,ultrasonic thickness gauge ราคา, ultrasonic thickness gauge คือ | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-2A A-SCAN (NOVOTEST) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-2A A-SCAN (NOVOTEST)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-1M-ST (NOVOTEST) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-1M-ST (NOVOTEST)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-1M-IP (NOVOTEST) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-1M-IP (NOVOTEST)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-3M-EMA (NOVOTEST) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-3M-EMA (NOVOTEST)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-1M (NOVOTEST) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model UT-1M (NOVOTEST)  Ultrasonic Thickness Gauge UTG เครื่องวัดความหนาโลหะ Model UTG-M UTG-C1 UTG-C UTG-M Ultrasonic Thickness Gauge UTG เครื่องวัดความหนาโลหะ Model UTG-M UTG-C1 UTG-C UTG-M  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM 210 PLUS Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM 210 PLUS  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM 210B Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM 210B  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM 8818 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM 8818  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model CM 8812C Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model CM 8812C  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model High Precision Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model High Precision  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM 230D TM 250D Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM 230D TM 250D  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-2 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-2  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TI45N Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TI45N  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TG110 DL Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TG110 DL  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TG210 TG410 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TG210 TG410  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ iThick-7000 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ iThick-7000  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ iThick-220 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ iThick-220  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ADL UT-20 (ADL) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ADL UT-20 (ADL)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TI-45NA Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TI-45NA  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25MXT (CHECKLINE) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25MXT (CHECKLINE)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25MX (CHECKLINE) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25MX (CHECKLINE)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25DLXT (CHECKLINE) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25DLXT (CHECKLINE)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25DLX (CHECKLINE) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25DLX (CHECKLINE)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25SX (CHECKLINE) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25SX (CHECKLINE)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25PX (CHECKLINE) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25PX (CHECKLINE)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25LTX (CHECKLINE) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ TI-25LTX (CHECKLINE)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-1500 (Phase ll) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-1500 (Phase ll)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-2900 (Phase ll) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-2900 (Phase ll)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-2675 (Phase ll) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-2675 (Phase ll)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-2800 (Phase ll) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-2800 (Phase ll)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-4000 (Phase ll) Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ UTG-4000 (Phase ll)  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Flaw Detector TFD-800C Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Flaw Detector TFD-800C  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Flaw Detector TFD-900 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Flaw Detector TFD-900  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM-281 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM-281  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model VX Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model VX  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model PX-7DL Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model PX-7DL  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model PX-7 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model PX-7  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MMX-6DL Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MMX-6DL  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MMX-6 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MMX-6  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-5DL Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-5DL  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-5 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-5  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-3 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-3  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-1 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MX-1  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MMX-7 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MMX-7  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MVX Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model MVX  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model PVX Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model PVX  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model CMXDLP Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model CMXDLP  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model CMXDL Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model CMXDL  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model CMX Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model CMX  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model PZX-7 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model PZX-7  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-6DL Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-6DL  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-6 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-6  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-5DL Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-5DL  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-5 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-5  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-3 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-3  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-2 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-2  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-1 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model ZX-1  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-406 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-406  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-405 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-405  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-600 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-600  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-403 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-403  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-440 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-440  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-430 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-430  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-420 Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model Minitest-420  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model SH-21 Japan Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model SH-21 Japan  Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM8812 TM8812C Ultrasonic Thickness Gauge เครื่องวัดความหนาโลหะ Model TM8812 TM8812C |